Just-in-Time deliveries as a service

Etusivu » Services » Internal logistics services » Just-in-Time deliveries as a service

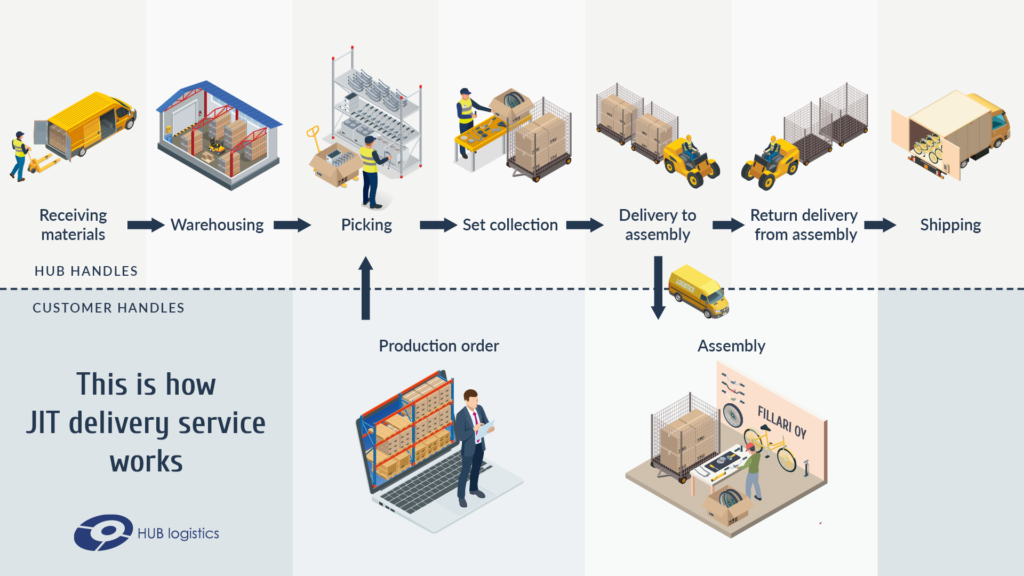

When products are manufactured in industry, they are usually assembled from components and various parts. The parts are in the warehouse. With HUB’s Just-In-Time (JIT) delivery service all parts and components are collected from the warehouse and brought to assembly – the right amount at just the right time.

JIT delivery service is one of the services offered by HUB logistics. It is preparatory work, which enables better focus on assembly. A lot of JIT delivery is done in industry, where, for example, crane or pump parts with screws and bolts are collected and delivered, but the concept can be applied to many sectors.

HUB logistics does JIT delivery services, for example, in Lahti Central Hospital, where supplies and protective equipment are delivered to the treatment rooms and operating theatres. Set collection as a service is chosen when the customer has a clear aim to develop production.

JIT delivery service bring efficiency to production

JIT delivery service brings efficiency and clarity into production as right people get to do right things in which they are professionals.

Advance planning is the most important step in JIT delivery service. Planning involves checking the correct timing on the basis of which the service can be done. We describe the process, identify the customer’s end products and their components, and estimate how many of each product is manufactured and how much of each product is moved.

During the planning phase, concrete lines are drawn to show, for example, where the warehouse trains move and where they stop. Often, the concept is initially piloted on a single production line with a complete finished product, from which it is then expanded.

It all starts with the customer’s needs. Our job is to go through the whole operation and fully understand how the process works.

JIT delivery service as part of in-house logistics

Manyfactory part picking is mostly done at the customer’s premises, but also at HUB logistics’ own warehouses – depending on the customer’s situation and the size of the operation.

If the customer’s production facilities run out of space and more space is needed for production, the warehouse can be moved elsewhere. For example, next to the factory. If it is not possible to build a new warehouse, the aim is to organize production facilities more efficiently and create separate areas for production and storage. Sometimes manufactory part picking takes place further away in HUB logistics’ own warehouse, from where the material is delivered by truck to the production point.

The most important benefits of JIT delivery service

- Right people do the right things. Results are better when a professional can focus the core task.

- Right amount of parts and components are in use at the right time.

- Better materials management. It is expensive and unefficient, if products cannot be assembled.

- Cleanliness of premises. Waste generated is removed and recycled with return logistics.

Leave us your contact information and tell us about your logistic needs.

Read more about internal logistics services:

This is how manufactory part picking works: materials are in the storage. WMS tells what materials are needed and parts are collected from the storage to a warehouse train or cart. Set is brought to assembler at just the right time and the assembler can focus on his own work.

JIT delivery service is suitable for many sectors

There are many terms associated with Just-in-Time delivery service and manufactory part picking service. The concept could be called, for example, production service, factory service, assembly service, spare parts service, component service, on-demand service, on-demand supply, on-demand selection, production feed or factory feed. Timing is essential. Hence the logistics term Just In Time, i.e. timely delivery, is involved.

HUB logistics’ manufactory part picking services cover a wide range of products, from screws and bolts to large components. Customer’s need or the end product can be anything. We have supplied parts and accessories to the assemblers at a car factory, and on the other hand we make sure that the hospital’s treatment room has the necessary supplies at the right time.

The information about what belongs to a particular set comes from the customer’s systems. The more complex the structure of the product and the variation in components, the more challenging it is to carry out the service.

HUB logistics can Just-In-Time delivery service all the way through

Strengths of HUB’s JIT delivery services are competent design team, strong system support and own functional concept. Premises and equipment are organised based on customer’s needs.

As our customer, you will see the result of JIT delivery as right materials are delivered to assembly at the right time. Collecting parts is carried out according to orders in the WMS.

Performing JIT delivery service requires good advance planning. We gather an experienced team to plan your logistics. We are happy to tell you more. Do not hesitate to contact us, if you wish to hear more.

HUB logistics is a comprehensive partner for internal logistics and material flow management. We offer high quality warehousing and logistics. As our client you will receive intelligent logistics and warehousing just for your needs. We will handle all stages of your company’s logistics efficiently and with high quality.

Do you want more information about JIT delivery services?

Smart logistics is everyone’s advantage

Automation, digitalization and intelligence are developing logistics strongly right now.

HUB logistics planned layout and processes to Sulzer’s new logistics center

Sulzer Pumps Finland Oy launched an investment project in the

Just-In-Time delivery service brings efficiency and clarity to your business – but what is it really?

A set is a collection of things that belong together.